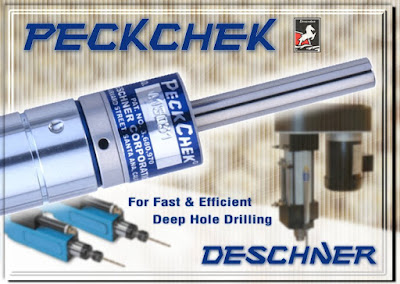

Drilling to a depth of more than three times (3X) the drill diameter often requires peck drilling where the drill is repeatedly withdrawn to remove waste cuttings while being advanced in steps deeper and deeper during each feed movement. Deschner PeckCheks were designed specifically for use in these deep hole drilling applications.

The plunger rod on a standard Kinechek speed regulator is designed to automatically extend with every stroke. But for efficient peck drilling, the Kinechek speed control function must be restricted to occur only when the drill is cutting. Therefore, the plunger rod remains in position while the drill retracts to clear the chips away. By design, there is a slight extension of the rod (approx. .005 inches) to prevent the drill bit from impacting the work piece. This is an especially important feature when using smaller drilling tools. This tiny gap allows for the speed control function to engage before the bit re-enters the hole, preventing bit breakage. The PeckChek Control in conjunction with a special Kinechek is designed to operate in this manner.

The PeckChek Control is a one-way ball clutch that prevents the automatic extension of the plunger rod. It fits over the plunger rod and attaches to the body. However, PeckChek Controls must be used only with special Kinecheks that use plunger rods that are hardened full length, to withstand the brinelling action of the ball clutch, and are approx ½” longer in length to accommodate the PeckChek Control without loss of controlled stroke. Although the PeckChek Control when mounted on the special Kinechek forms a single unit, the PeckChek Control is sold separately from the Kinechek. This is because the same PeckChek Control can be used on Kinechek models numbers having different stroke lengths. PeckChek Controls are available for use with Slimline, Super K and Mini K Kinechek Models.

SEE ALL ABOUT THE PECKCHEKIN THIS YOUTUBE VIDEO

https://youtu.be/DwWZnh9csjY

DOWNLOAD PDF OF DESCHNER PECHCHEK SPEC SHEET

STANDARD http://deschner.com/wp-content/uploads/PeckChek-Full-Bulletin.pdf

METRIC http://deschner.com/wp-content/uploads/S-62-M-PeckChek-Bulletin-2017.pdf

MORE INFORMATION ABOUT THE DESCHNER PECHCHEK

PeckChek Animation Sequence - https://youtu.be/qRapOBw9UeE

Specialty Kinecheks - http://deschner.com/products/specialty-kinecheks

OTHER YOUTUBE VIDEOS USING THE DESCHNER PECHCHEK

AutoDrill Two Hole Peck Drilling Process - https://youtu.be/JXzTFFSr5bM

AutoDrill 100 0061 - https://youtu.be/H0GnWRYmHgE

Deschner Corporation

714-557-1261

1-800-457-6666

info@deschner.com